What are the advantages of MCM sheets compared with ceramic thin plates?

Thin plates are new building materials that have emerged in recent years. They are upgraded products of ceramic tiles and also belong to the category of ceramics. Although thin plates are advertised as low-carbon products, that is relative to traditional ceramic tiles. In the production process, they also need to be fired at a high temperature of thousands of degrees, which consumes a lot of energy, so the future development space is also narrow.

Compared with them, MCM sheets have the following advantages:

More environmentally friendly production:

In production, MCM sheets consume less energy than thin plates, and are more environmentally friendly and low-carbon.

More affordable prices:

The price of thin plates is much higher than that of MCM sheets, and the price is higher in terms of comprehensive costs.MCM sheets are widely used, and can be used on walls, floors, ceilings, columns, etc.

Wider application:

At present, there are many limitations in the application of thin plates. The largest range is mainly used on walls, and the market is still relatively small.

Better performance:

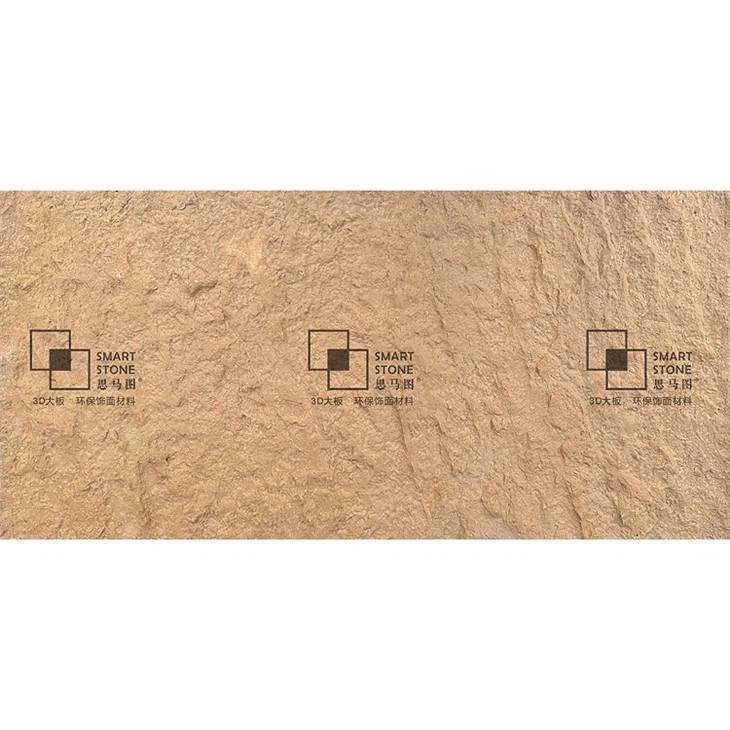

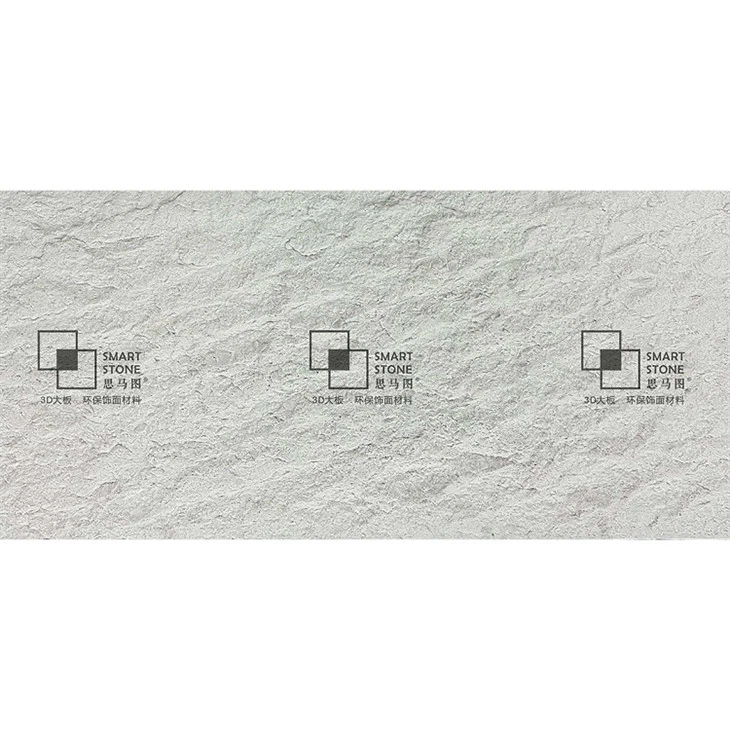

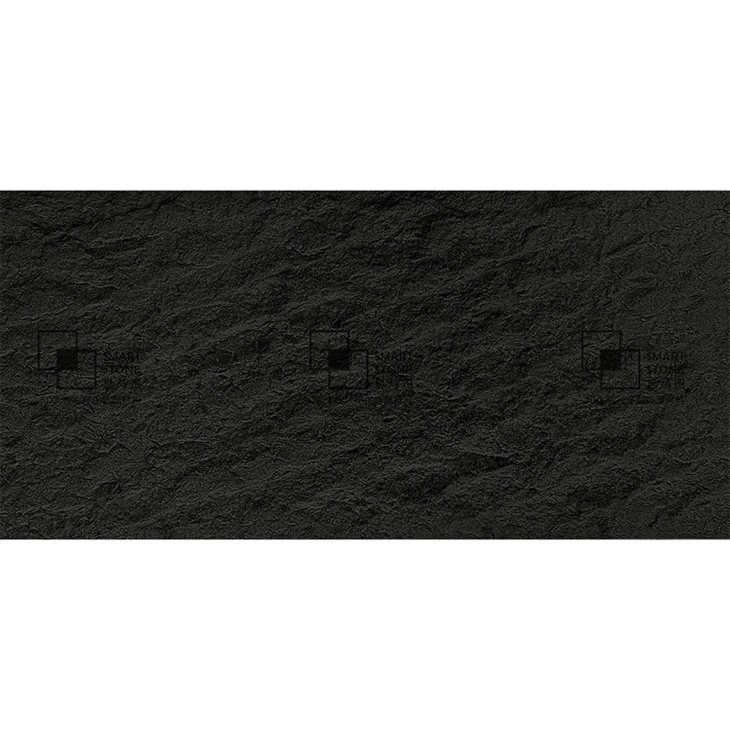

Thin plates are not impact-resistant and cannot be bent. Compared with thin plates, MCM ecological ceramic plates have stronger impact resistance and can be used for various special-shaped structures.

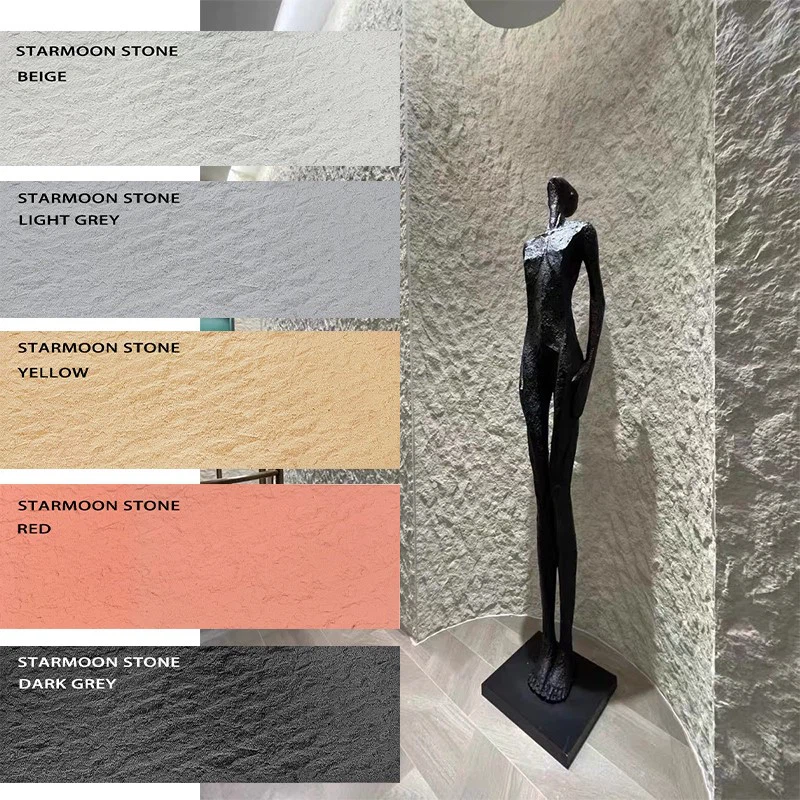

Product Features

Flexible stone series with concave and convex patterns or sandy surfaces, such as ceramic panels, slate, travertine, sandstone, clear water rock, wood grain rock, art rock and other products, should be cleaned during construction. The surface should not be contaminated by adhesives, cement, coatings and other materials, otherwise it will be difficult to clean. Construction workers should keep their hands clean, because the surface of soft ceramic products for floor decoration is semi-vitrified, and should be prevented from being drenched by rain within 24 hours after pasting to avoid contamination.